| Fuel tank :

A key part of any fuel system is the fuel container

itself. The debate is whether to use a modified USCG

approved fuel tank or install a racing fuel cell.

There are several benefits for retaining the stock fuel

tank in a high horsepower Marine craft. It has a larger capacity

than most fuel cells, already has a mounting location and hardware, has

provisions for filling from outside the craft, has a cap that both

vents and seals and is already on/in the craft.

The drawbacks of using a common USCG approved fuel tank

are more numerous but less obvious. The stock pick-up / pump

assembly is restrictive, requiring complete replacement with a

fabricated assembly. When using a stock tank with fabricated

pickup, unless the fuel level in the tank is ¾ full or higher, the

internal well, which the stock pump draws from, is far too small and

poorly supplied with fuel from the rest of the tank. Faced with

the demand of a large pump, drawing through a fabricated pickup, it has

no chance of refilling fast enough to support WOT full engine

load. Under low demand, e.g. cruise type conditions, the large

volume of fuel delivered to the carburetor or rails is unused and

returned. The same fuel, picks up heat from the pump and the

rails, is constantly recycled to and from this tank, which will rapidly

increase fuel temperature. Common problems associated with stock

fuel tanks and fabricated pickups are pump cavitation, vapor lock,

varying fuel pressure, exaggerated pump wear and lean conditions during

both low and high loads. Note: Unlike a carbureted engine, any loss of

fuel supply at the in-tank- pickup will immediately result in a loss of

fuel volume and pressure at the EFI injector resulting in lean

conditions and engine damage.

Most of us will be stuck with a stock style fuel

tank since they need to be USCG approved to qualify for a marine craft

, you look at a common layout of 3/8" pick up line with anti syphon

valve as "Pick up". This pick up is restraining your fuel flow at the

same source where it should flow free. Your tank will most likely have

a 1 1/2" fill and 5/8 " vent tube molded into

the tank. Here we are still missing one more nozzle for the

cozy/warm return line.

Until the tank manufacturers have changed their tank design to

provide bigger diameter pick up lines and a return line nozzles, we can

only modify it to fit existing needs. We can use the 5/8" vent tube and

modify it to the pick up line, lets not forget to install a anti

syphon valve before we go to the filter / pump. Use the 3/8" pick up

line as vent ( make sure to get rid of the pick-up tube molded into the

tank) and "T" into the 1 1/2" fill line your return line at the

closest point to the tank. As the pump will start to pick up fuel from

the tank, the fuel volume will decrease. Any excess fuel from your

carburetor or EFI injectors will be returned into the tank and the

warmer fuel will mix with the fuel in the tank. Do not "T" your return

line just before the fuel pump since that will send high amounts of

fuel continuously through the fuel pump to heat up more till it will

reach critical temperature. Unfortunately with this

modification, you have changed the once USCG compliant tank into

your own piece of art.. Even though this piece of art might do

the job but you are not USCG compliant anymore.

With this set up the primary problem of heat soak is minimized.

However, this is still a compromise at best, requiring fuel levels be

maintained above ¼ for normal low engine load, above ½ to ¾ for

racing . In all serious racing applications the correct fuel cell

is highly recommended.

|

| Fuel Intake

filter:

Or intake filter - Most people regard fuel filter as the

first line of defense against contaminated fuel. Personally, I believe

it is the last line of defense which often produces more problems

than it solves. This part of the fuel system file is regarding non

diesel application which have a bigger set of problems.

Before you actually fill fuel in your tank, make sure the tank and the

fuel is clean. Use a strainer every time to fill the tank and

close fill cap after filling.

A good recommendation from Aeromotive fuel system

is that the filtration media to be used on the inlet side of a

fuel pump may be no smaller than 100 micron and must have an element

surface area of 60 square inches or more. Any filter element not

meeting these criteria may fail to flow the full volume of a high

capacity fuel pump being used, resulting in cavitation at the

pump inlet. Most high capacity fuel pumps are extremely efficient by

design, allowing them to create high pressure on the outlet and high

vacuum on the inlet side, if restricted. Cavitation can be to a

pump like detonation is to an engine and occurs when the liquid being

pumped reaches a temperature where it boils and starts to

vaporize. The temperature at which any liquid boils varies with

pressure. Recall that water in a radiator is purposely

pressurized to raise the boiling point. When was the last time

your high pressure EFI system vapor locked? Keep in mind, as a

pump pushes it has to pull. When a pump has to pull too hard

acquiring fuel, a vacuum or low-pressure area develops at the

inlet. The better and more efficient the pump is, the lower inlet

pressure will fall. The boiling point of any liquid fuel in this

low-pressure zone falls as well. With a highly efficient pump,

inlet pressure can get so low that fuel will boil and the pump will

cavitate at normal operating temperatures. Today's ultra-high output

engines require equally high efficiency fuel pumps. Failure to

install them properly can be costly in two ways: First, during

cavitation the engine may experience a momentary lean condition (loss

of liquid fuel pressure and volume). Second, excess heat and

friction will build in the pump, causing damage and eventual

failure. If you feed your pump properly it will feed your beast

for years to come! Review your installation and make sure the

pump is mounted where gravity will help push fuel to the inlet, use the

correct size AN line between the tank and the pump and install filters

that flow the necessary volume freely. In some marine applications you

will find a whole set of filters before the actual pump, make sure your

filters are cleaned and cartridges replaced on a regular basis.

|

| Fuel pump :

The performance of your whole fuel system depends upon

the fuel pump. Selecting the right fuel pump is of the out most

importance to your high speed water craft's performance.

The critical factors that effect fuel pump selection are

numerous. In the past, fuel pump manufacturers have rated their

offerings based on gallons-per-hour, free-flow (no test pressure), and

with no reference to test voltage. In the real world, this gives

no indication of the horsepower that could be supported by such a pump.

The key variables that determine which fuel pump is suitable for a

particular engine combination are:

- Engine flywheel horsepower.

- Engine fuel efficiency, commonly referred to as BSFC

or Brake Specific Fuel Consumption.

- Maximum fuel system pressure and the pump's flow

volume at that pressure.

- Available voltage at the pump under engine load and

the pump's flow volume at that voltage.

The first step is to establish how much horsepower will be produced and

the amount of fuel required to support it. To be safe, start by

estimating HP on the high side and efficiency or BSFC on the low

side. A typical gasoline engine will use less than 1lb of fuel to

make 1 HP for 1 hour, so expect the BSFC number to be less than

1. Different engine combinations, power adders, even fuel octane

ratings and tuning approaches will have a profound impact on

BSFC. Consider this carefully when choosing a fuel pump.

You may use the following information as a guideline,

however these are simply observations. The best, and our

recommended, method of establishing actual BSFC is through proper

flywheel dyno testing.

- Naturally aspirated engines are normally most

efficient with a BSFC between .4 and .5 lbs/hp/hr.

- Nitrous combinations use a little extra fuel and

often develop a BSFC from .5 to .6 lbs/hp/hr.

- Forced induction engines are usually least

efficient and BSFC ranges from .6 to .75 lbs/hp/hr.

Using 650 HP, lets figure the fuel requirement for the most vs. the

least efficient engine combination.

- 650 HP multiplied by a .4 BSFC equals 260 lbs

of gasoline.

- 650 HP multiplied by a .75 BSFC equals 487 lbs of

gasoline.

As you can see, the amount of fuel required to support two different

engines, each making the identical amount of HP but with very different

fuel efficiencies, virtually doubles the volume of fuel required!

Note: It is equally important to consider BSFC when

determining minimum injector size. To calculate, divide the lbs

of gasoline required by the number of injectors used. If you are

estimating, it pays to be safe. Many engine builders will add a

percentage to total fuel pump volume for safety and then divide the

minimum injector by .8 in order to target about 80% injector duty

cycle. This allows consistent injector performance, cooler

operation for enhanced durability and leaves about 10% for unexpected

power.

For example:

- 650HPx.4 = 260lbs. 260lbs/8

injectors=33lbs/hr. 33/.8=41lb/hr injector @ 80% duty cycle.

- 650HPx.75=487lbs. 487lbs/8

injectors=61lbs/hr. 61/.8=76lbs/hr injector @ 80% duty cycle.

It is imperative to consult with an experienced engine builder when

estimating HP and making these calculations. There's a lot at

stake and errors can result in serious harm to the engine and those

around it.

Determining the fuel volume necessary for a particular

engine is the first step in selecting a fuel pump. If the

combination is naturally aspirated, does not use rising fuel system

pressure and has a correctly sized alternator in good working condition

it may be OK to stop here. If not, there's still more to

consider.

The second step is to establish what the base fuel

pressure will be and if, as with forced induction or certain "dry

nitrous" kits, pressure will be required to change with engine load.

How does fuel pressure affect pump delivery? You can bet that as

system pressure goes up the pump’ volume will go down.

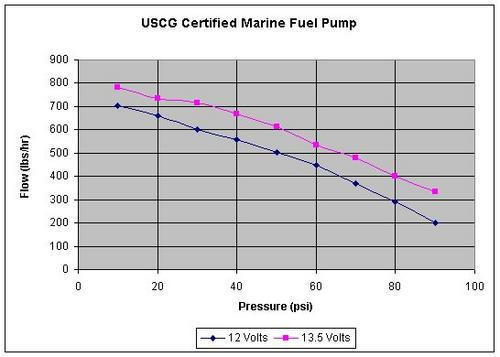

To illustrate this, take one of the most popular and

efficient EFI pumps on the market, Aeromotive’ A-1000 part

#11101. Lets examine various pressures to demonstrate the effect

this has on flow volume:

- Carbureted, Nat Aspirated, 9psi and 13.5v, volume

791lbs/hr. 1,582 HP @ .5 BSFC.

- EFI, Nat. Aspirated 43.5psi and 13.5v, volume

614lbs/hr. 1,228 HP @ .5 BSFC.

- 20psi boost/1:1 Regulator, intercooler, 60psi and

13.5v, volume 529lbs/hr. 881 HP @ .6 BSFC

- 10psi boost/4:1 FMU, intercooler, 80psi and 13.5v,

volume 426lbs/hr. 710 HP @ .6 BSFC

- 6psi boost/8:1 FMU, intercooler, 91psi and 13.5v,

volume 370lbs/hr. 616 HP @ .6 BSFC

Measuring a high efficiency fuel pump such as "HP Marine

USCG Fuel Pump P/N 11108" , from 9psi to over 90psi, flow volume is

reduced a total of 53%. Comparing volume at 60psi for a high

boost kit with correct injectors to 90psi for a low boost application,

with small injectors and an FMU, volume is reduced by 28%.

Clearly the effect of rising fuel pressure has significant impact on

flow volume. What is not shown (and rarely published) is the

devastating impact this has on less efficient, traditional pumping

mechanisms. It is obvious that eliminating unnecessary fuel

pressure rise, e.g. removing an FMU and installing the correct

injector, increases flow, maximizing the HP potential of any fuel

system.

Clearly the effect of rising fuel pressure has significant impact on

flow volume. What is not shown (and rarely published) is the

devastating impact this has on less efficient, traditional pumping

mechanisms. It is obvious that eliminating unnecessary fuel

pressure rise, e.g. removing an FMU and installing the correct

injector, increases flow, maximizing the HP potential of any fuel

system.

This brings us to our third fuel pump performance

factor; voltage supply as measured at the fuel pump terminals.

Voltage to an electric motor is like fuel pressure to an injector, more

pressure in equals more volume out. Higher voltage at the pump

terminals increases motor torque, resulting in more rpm and an

increased flow volume for a given pressure. To illustrate this,

lets use again the above Aeromotive marine fuel pump at 80psi will see

a 40% increase in volume when voltage is increased from 12v to

13.5v. This factor is often overlooked and can make or brake pump

performance, especially at high pressures. The key here is to

figure flow at voltage if an alternator is used or not. As

Hovercraft can fly where no other transportation means can go - you

know you are the only one out there.

Just imagine if your alternator fails and and on your return trip

voltage will drop. If the voltage of your slowly discharging battery

reaches the critical aspect where your pump can't build sufficient

pressure to supply the engine with fuel. I guess you are stuck for

good. In case of a recreational craft you can make a nice adventure out

of it, in case you run a charter / taxi service you will need

good legal representation.

Dynamic vs. Static

fuel systems: EFI efficiency for carburetors.

CARBURETORS STILL RULE in many forms of racing and on

many cruising machines. Those who choose (or are required) to run

a carburetor are turning to expensive, custom-built models for better

performance. Often the custom shop will advise a fuel pump

upgrade, usually suggesting a pump rated to flow as much as 4-6 times

the amount necessary to support the engine’ horsepower. Normally

the quick explanation for this is the need to overcome acceleration

G-forces.

Hold in mind you can spin your Hovercraft like a donut on water or hard

surfaces. That you can do this is your pure fun, pleasure and

entertainment - just under this condition your standard fuel pump has

to work overtime. Your fuel tank is most likely located as close as

possible to the CoG of your craft, way down in the bilge area. Your

fuel pump is located aft at the engine compartment. As long as the tank

is aft of the Cog centrifugal forces are no major aspect, once the fuel

tank is forward of the CoG centrifugal forces will first help the pump

- before she has to overcome the centrifugal forces which force the

fuel away from the CoG.

The least aspect you want to worry while you enjoy the donut flight is

a dying engine because of low fuel pressure. Which would eliminate any

control over your craft and most likely a bit wet plow in as you loose

lift air.

The fuel systems first priority is to keep the floats

from running low enough to uncover the main jet, running the engine out

of fuel. Traditional, static systems do a fair job of this.

The second, more difficult priority is keeping the fuel level optimum

in the bowl. It may not seem significant but the weight of fuel

above the main jet does impact fuel flow through it, and therefore the

air/fuel ratio of the engine under load. The sophisticated

carburetor racer knows the float bowl must always be as full as

possible. This is critical if engine tune is to be held across

the rpm band, achieving peak performance throughout the race. An area

of special focus for racing crafts is the time before

getting over hump speed following launch. Here the typical static

fuel system struggles. The fuel is standing in the line, barely

moving and to make matters worse, the static style regulator places the

check valve between the fuel pump and carburetor, restricting fuel flow

across the board. To combat this, fuel pressure in a static

system is always held higher from the pump to the regulator (12-60psi)

than it is from the regulator to the carburetor (3-7psi). This

higher line pressure is necessary for two reasons, one to start flow

against G-force and two, to push fuel through the restrictive regulator

valve. A return style regulator places the inlet and outlet ports

above the check valve with only the return volume having to flow

through the restriction. As a result, the pressure from the pump

to the regulator is the same as from the regulator to the carburetor

(3-7psi), allowing the pump to speed up, increasing volume

significantly, and supplying full output directly to the float bowls at

all times.

The benefits of a dynamic, return style fuel system are

numerous, including longer pump life, a marked increase in pump to

horsepower ratings (allowing smaller, lighter pumps to fuel more HP),

even quieter pump operation is common. Ultimately, combining a

high quality marine fuel pump and return regulator into a dynamic

fuel system significantly improves average float level, fueling the

bowls more quickly and consistently. The bottom line is the

finish line and getting there first with a more constant air/fuel ratio

across the rpm band and more predictable power all the way down.

|