This script shall give you a basic idea of a simple hydraulic

system ( also known as fluid power system ) for single engine

hovercraft. The hydraulic system is used for separate lift fan

operation.

It is not a working copy to set up any system and shall provide you

only with the basic idea and some tips in the layout - please consult a

hydraulic specialist for detailed calculations and project specific

layout.

You will find some required calculations and formulas in

the linked pdf files.

The basics :

A hydraulic system consist of a hydraulic pump and motor.

The pump is attached to

the main engine. The shaft of pump is connected to the engine shaft via

reduction or belt drive.

With each revolution of your main engine, the hydraulic pump is brought

into pumping motion.

It is important to take care of the pump max. rated RPM which in most

cases, will require a reduction drive. Hold in mind that you will need

adequate RPM for your lift unit before you reach high RPM on your

thrust output shaft. As well as max. thrust shaft RPM should not exceed

max. rated pump RPM.

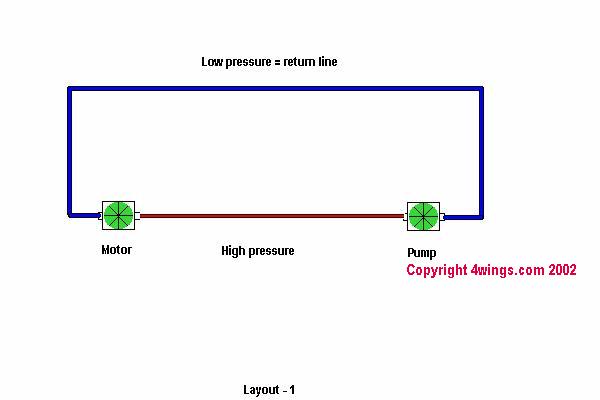

The pump is connected via

hydraulic fluid line to the hydraulic motor. This is your

high pressure line. For further reference please use : Eaton Pressure-Flow Compensated Piston Pumps all

credits to the original source.

The motor most likely

will be attached to the fan shaft directly or in the shortest possible

way. As the hydraulic pump builds up pressure with each rotation,

the high pressure line transfers this pressure to the intake side of

the motor which will start turning in a nearly equal manner ( minus

loss of friction in the line,...). For further reference please see

: Eaton Medium Duty Piston Motor - all credits to

the original source. The low pressure line is attached to the motor's

exit port and it will transfer the hydraulic fluid back to the pump as

seen in layout 1.

Alternative supplier are :

POCLAIN

HYDRAULICS INDUSTRIES

Sauer-Danfoss

CROSS

Manufacturing, Inc.

KNF Neuberger, Inc.

(USA)

Parker Mobile Hydraulics

This is the most simple set up of fluid power in a closed system. Kind

of stripped down basics which will work on very low hp

application and with generally no major control over your system.

This is the most simple set up of fluid power in a closed system. Kind

of stripped down basics which will work on very low hp

application and with generally no major control over your system.

To set up your system you need to know the max. HP and RPM on your

motor side - once this is known you can work yourself to the pump side.

I hope you could still follow so we can start to complicate this quite

simple system a bit.

Lets start with the motor - what else is there to take care of besides

low weight and long lifetime for a reasonable price?.... Most motors

won't be sitting on the shelf and have a 8 - 10 week delivery time - so

it is wise to get the right unit in the first place. Make sure you know

the shaft turning direction, location of the motor and most appropriate

( high pressure and low pressure ) port direction so you can reduce 90

degree elbow on the high pressure side. Make sure your drain port

point's up to drain air from your hydraulic system. Last but not least

motor attachment is important.

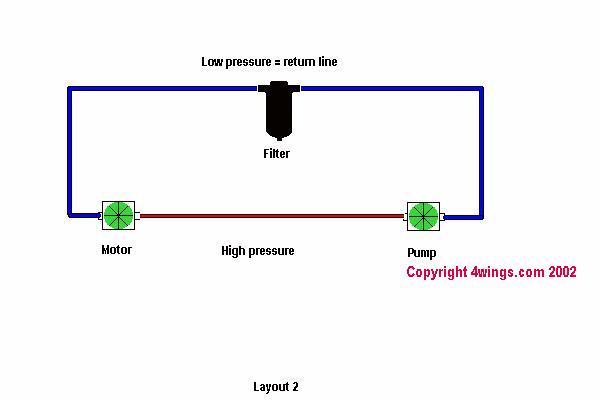

Filter:

Once we have this selected it is wise to think about the most important

medium in the system and that is your hydraulic oil ( try to use a good

non foaming oil ) . With the use of pump and motor you will get small

amounts of abrasion particles in your hydraulic oil - these tiny

buggers surf your oil and get pumped in equal manner through your

system as the oil it is in - so the use of a filter unit will increase

the lifetime of your hydraulic pump and motor and allow these buggers

to get out of the system. The filter unit will provide a certain amount

of resistance to your hydraulic oil flow.

For further reference please see : Low,

Medium & High Pressure Filters from Eaton Hydraulics - all

credits to the original source.

Your filter unit should be on the low pressure side - as seen in

Layout 2 - and is most likely close to the pump. Make the filter unit

easy accessible to change filter cartridges on a regular basis. As your

filter clogs up over time, resistance will increase in your system.

Other aspects you want to know about your hydraulic oil is

hydraulic oil pressure, hydraulic oil flow rate and the

temperature of your hydraulic oil.

In general - the more you know about your hydraulic oil the easier it

is to avoid expensive components failure.

Alternative supplier :

HYDAC TECHNOLOGY

So we covered motor aspect, oil and some means to hold

it clean ... now lets look at the

hydraulic hoses ...

somehow we need to get the hydraulic oil from point A ( pump ) to point

B ( motor ) and again back through a few obstacles. Hydraulic hoses

need to have adequate cross section to reduce friction in the line (

friction = resistance = heat build up in your oil) For further

reference please see : Velocity and Pressure drop in pipes and especially

at the section : FLOW / VELOCITY NOMOGRAM - as well as : SAE

Hydraulic hose specifications (SAE J517) . Select the appropriate

cross-section from your motor's maximum required GPM. and PSI range.

Try to lay the high pressure line as straight as possible from pump to

motor. Try to avoid 90 degree elbows in your high pressure line. Now

you have the theoretical location of your hydraulic line - so check if

the hydraulic hose will be able to flex around all corners it is laid -

some high pressure lines have quite big minimum radius. You can bend

them but do not underestimate this and try to take care of it before

hand. A Hovercraft specific problem in the layout of your hydraulic

system is the balance of your craft ( CoG ). As your hydraulic pump

will be attached by some means to your main engine, it is most likely

off center. Your motor on the other hand will be either on Centerline

or off centerline - all are fixed weights which won't change during

operation - the location of the hydraulic lines allows you to

compensate your balance to a certain extent - low pressure lines are

lighter and more flexible than the high pressure lines. Last but not

least the common sense suggestions - don't run your hydraulic

lines under your fuel tank since hydraulic oil warms up quite

considerable and it is not the safest way to fly with hot fuel ...but

who knows some might enjoy an extra boost.

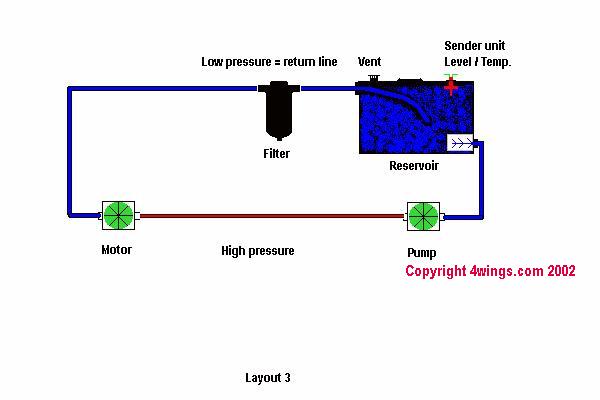

So far we have a system which has no leaks. But over the

service life of your system, this might change. As well as for

hovercraft applications you will run on high RPM = high GPM. =

relatively high PSI level which will break down your hydraulic oil ...

- the means to increase the lifetime of your pump and hydraulic

oil is a hydraulic oil reservoir tank.

This tank holds an amount of hydraulic oil and is vented to the

atmosphere. Unfortunately in a weight sensitive Hovercraft this tank is

dead weight and not appealing et all. Also it is a fact that custom

made tanks are not cheap. A good holding tank needs to have

certain features. The return line fitting which is attached to your

hydraulic hose, an internal extension which should extend in the

tank to the bottom of the tank to reduce foam build up. Internal thread

on the oil pick up side to attach a filter cat ridge, as well as

external threaded fitting to attach your hydraulic line feeding

your pump. As seen in figure Layout 3. The tank has to be located

above the pump to allow a gravity feed of hydraulic oil to the

hydraulic pump. An inspection hatch big enough to pass your hand

through ( a bit bigger would be handy so you don't loose your skin if

you clean your tank ). A vent on its highest point . And if you want to

go fancy, a thread to attach an oil level / temperature sensor would

make it safer. So you see we ask for a lot from the poor builder of

these tanks.

You can use an alternative with a basic factory tank

which has inline filter on the pick up side. But this will reduce the

life span of the tank. You must also discharge all the build ups

from the tank in an environmentally safe manner.

The sender unit in your

tank is more or less nothing more than an electric switch .

You have to determine first hand if the switch shall interrupt the

circuit ( as it would be useful if you run your ignition system over

the switch ) or close the circuit ( which is the case for a dashboard

emergency light or sound which should be activated when your level goes

low ) .

The appealing version is that in case the oil level drops ( the system

has a leak ) the sender unit would stop the main engine and damage

could be reduced to a minimum ... or you can run a red light to your

dash board ...... glue your eyes to it and hope you react quicker as

your pump is pumping the left over hydraulic oil out the leak..

Alternative supplier :

Temposonics -

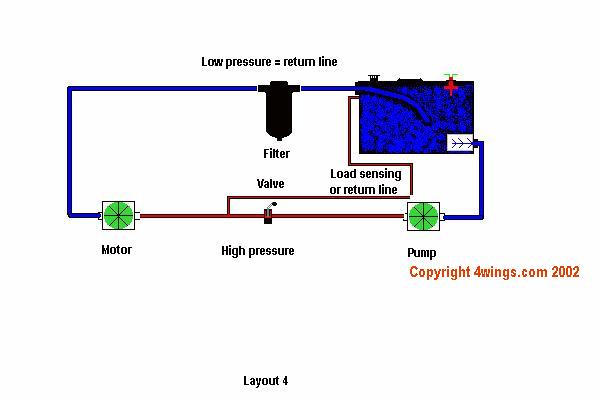

Even if our basic system got now quite complicated and

fancy - we still have no means of actual control of the system = any

difference in the RPM on the hydraulic pump shaft equals to

equivalent RPM change on the hydraulic motor shaft. The only means of

control in this aspect is a

Valve in the high

pressure line which regulates the fluid flow. For further reference

please use Vickers valves file - all credits to the

originator.

The valve - as seen in Layout 4 -should be the only component

between pump and motor in the high pressure side of the system. All the

valve does is to reduce or open the fluid flow to the hydraulic motor

but it cannot increase the flow beyond the pump capacity according to

it's input shaft RPM. The excess hydraulic fluid will be returned into

the holding tank. This process will heat up your hydraulic oil

considerably and more or less you burn unnecessary HP into heat. An

alternative is to use a pressure flow compensated pump with a load

sensing line as described in : Eaton Pressure-Flow Compensated Piston Pumps pages 25

and down - which will adjust fluid output according to

system requirements. But this variation exceeds the basic layout of

this file and might just complicate it unnecessarily.

Alternative supplier :

Marwin Valve

Flow-Tek

Conbraco

Kepner Products

Company

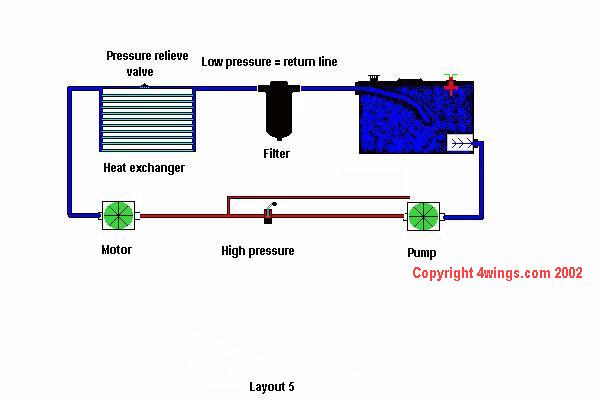

As you have seen in the description of most components -

they all have the nasty habit of changing a small amount of energy into

heat -for further reference please see : COOLING AND HEATING - from friction in the lines

to resistance in the filter units - your hydraulic oil will heat up

considerably if you have the system running on high RPM. This

heat needs to be anticipated to the environment via an adequate heat exchanger which will hold your

hydraulic oil temperature as low as possible. For further reference see

: Heat Exchangers for small systems or: Heat exchanger for bigger systems The heat

exchanger will be located in the low pressure side of your system and

either you have to use a heat exchanger with relief valve as seen in

Layout 5 - in case the unit clogs up - or two units in parallel. All

heat exchangers need direct airflow = airflow through the unit and not

over the unit which is something we do not really like to provide in

Hovercraft where we try our best to produce the highest mass flow of

air we can achieve with our HP.

This is a basic explanation of hydraulic systems , in case it

created a desire to get a more in depth knowledge , please

download the following file : "Hydraulic

systems in aircraft"

Distributor for hydraulic components :

Small HP ratings :

Northern

Tool

General aspect / high Hp ratings :

Motion

Industries

Unfortunately their web site is as useless as their service and staff

is useful - so just look up your nearest Service center and get "hands

on" with them.

|