| LUBRICATION

The engine lubrication system is needed to lubricate (and cool) the eccentric shaft journal bearings and the combustion chamber seals. Lubrication of the eccentric shaft bearings is similar to the lubrication of the crankshaft bearings for a standard piston engine. A separate oil metering pump is needed to lubricate the combustion chamber seals since they cannot be "reached" from the eccentric shaft.

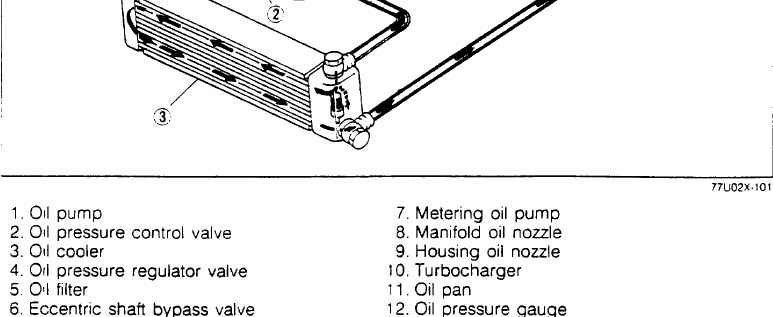

This diagram above shows the components of the engine

lubrication

system and the flow direction in a 13B Turbo. The oil is picked up from

the oil pan and circulated by the oil pump (inside the front cover) to

the oil cooler, oil filter, eccentric shaft, and back to the pump. Oil

is also supplied to the oil metering pump which injects oil into the

combustion

chambers via two pairs of oil injectors (one on the lower intake

manifold,

the other on the rotor housings).

MAIN COMPONENTS The oil pump which is located inside the front cover is driven by the eccentric shaft (via a chain). It is of the trochoid type with two sets of rotors (each set consists of an inner and outer rotor). It is interesting to note that the mechanics involved in the oil pump operation are similar to those involved with the rotary engine itself. The oil cooler enables the cooling of the lubrication oil. The flow of oil into the cooler is controlled by the oil cooler bypass valve. Note that the oil cooler lines are often the causes of leakage. The eccentric shaft has two (diametrically opposed) off axis round lobes in correspondence with the rotor bearings. Each round lobe turns (around the shaft axis) as the associated rotor turns around (in a cyclical fashion) its stationary gear. The eccentric shaft is in contact with two main bearings (front and rear) and two rotor bearings (at the lobes). In order to lubricate these bearings, there are oil passages at the level of each of them. There are two oil seals for the shaft (front and rear): one is in the front cover and the other is in the rear stationary gear. As a side note, each rotor has two oil seals per side to prevent oil to from the shaft to go into the combustion chambers. Passage of the oil into the eccentric shaft is controlled by the eccentric shaft bypass valve (its failure would obviously be a disaster). The (mechanical) oil metering pump allows oil to be injected in the combustion chambers to lubricate (and also cool) the rotor seals (apex and side). A rod connected to the throttle plates regulates the amount of oil to be injected. The more open the throttle plates are, the more oil is injected. For each rotor (front and rear), there are two injectors: one is located in the (lower) intake and the other is placed at the top of the rotor housing. There are therefore a total of four injectors. |