| ENGINE COOLING SYSTEM

The cooling system is needed to prevent engine overheating. It is a closed (pressurized) system with a coolant recovery reservoir. Having the cooling fluid under pressure raises its boiling point, which allows the engine to operate at higher temperatures (making the engine more efficient) without any boiling of the fluid. The cooling fluid is a mixture of water and ethylene glycol (usually, a 50/50 mix).

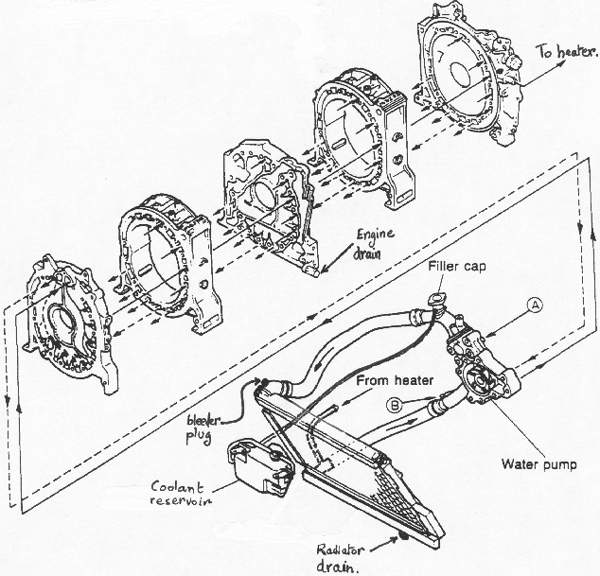

This diagram above shows the components of the cooling

system

and the flow direction of 13 B second generation engine) . When the

thermostat

is closed (cold engine), the fluid goes from the water pump to the

engine

block and back to the pump. When the thermostat is open (hot engine),

the

fluid goes from the water pump to the block, upper radiator hose,

radiator,

lower radiator hose, and back to the pump.

MAIN COMPONENTS The water pump circulates the cooling fluid through the cooling system. A quick way to test for its proper operation (assuming the thermostat is open, that is, engine is hot) is to squeeze the upper radiator hose and feel the surge as the hose is released. Coolant leakage from the weep hole on the underside of the pump indicates a failing pump seal. The (pressure) filler cap enables the system to relieve itself in case of excessive pressure. When the pressure in the cooling system exceeds a certain limit, the filler cap allows coolant to escape to the reservoir. This typically happens when the coolant temperature is past the boiling point and the coolant starts to boil (generates high-pressure steam). When the pressure in the system becomes negative (system is actually under vacuum), the filler cap allows coolant from the reservoir to be drawn into the cooling system. This typically happens after cool down of a system that has boiled over. The (pellet type) thermostat regulates the cooling power of the cooling system. When the engine is cold, the thermostat is closed to allow for the engine to warm up as fast as possible. When the engine nears its normal operating temperature (about 180 degrees F), the thermostat starts opening in order for the coolant to start being cooled down (by going through the radiator). The thermostat is fully open when the temperature reaches 203 degrees F. COOLANT FILLING

PROCEDURE OF THIS

SYSTEM:

It is recommended to change engine coolant every 30,000 miles. The refilling has to be properly done in order to avoid the introduction of air into the system. The correct procedure is as follows (assuming the radiator drain plug and engine drain plug are in place): * place heater control to maximum heat

|